THIS IS THE U.K. HISTORIC ARMS RESOURCE CENTRE ............. FREE OF COOKIES, TRACKING & ADVERTISEMENTS

Please be aware that some specialist rotational imagery on these pages may take longer than usual to load

LEE-ENFIELD No.8 RIFLE - USER HANDBOOK

Return to: Rifle No.8 page

w.o.

Code No.

13217

User Handbook

for the

RIFLE,

0.22 in.. No. 8, MK. 1

Land Service

1961

This publication supersedes W.O. Code No. 10141

BY COMMAND OF THE ARMY COUNCIL

THE WAR OFFICE,

4th January, 1961

******************************************************

CONTENTS

*****List of illustrations ... ...... .........

.

**********Section 1 - General

Description

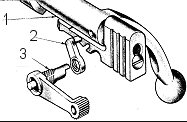

**Introduction ... .,, ...... .........

**** Technical details . ... ...... .........

*********Furniture and. external fittings ..

.........

Sights .. ... ... ... ...... .........

Bolt ... ... ... ... ...... .........

*Body ... ... ... ... ...... .........

******Trigger mechanism . ... ...... .........

*Barrel .. ... ... ... ...... .........

*v*Safety devices ... ... ...... .........

*Stocking ... ... ... ...... .........

*********Cartridge platform and ejector.. .........

******Conversion to L2A1 ... ...... .........

Section2 - Operation

**Loading ... ... ... ...... .........

..

*****Trigger mechanism . ... ...... .........

*Sear .. ... ... ... ...... ......... .,

*******Withdrawal of firing pin ...... .........

.,

*******Extraction and ejection ...... .........

..

Section3 - Servicing

*Stripping ... ... ... ...... .........

**Assembling .. ... ... ...... .........

****Adjustments .. ... ... ...... .........

..

**Stocking up .. ... ... ...............

*Zeroing ... ... ... ...... ......... ..

****Altering length of butt ...... .........

*****Care and cleaning . ... ...... .........'..

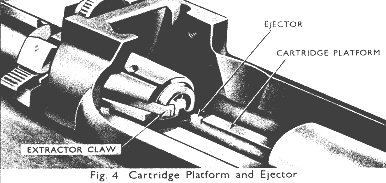

******Additional technical points .... .........

**Section 4 - Examination

Bolt ... ... ... ... ...... ......... ..

*Body ... ... ... ... ...... ......... ..

***Trigger group ... ... ...... ......... ..

**Furniture ... ... ... ...... ......... ..

******Section 5 - Competition

Shooting

*********************************************************

L1ST OF ILLUSTRATIONS

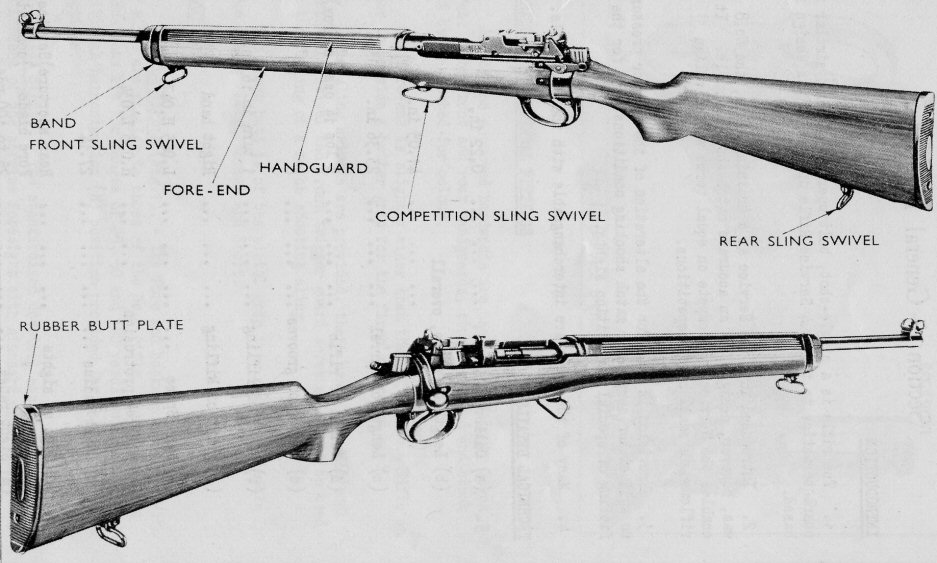

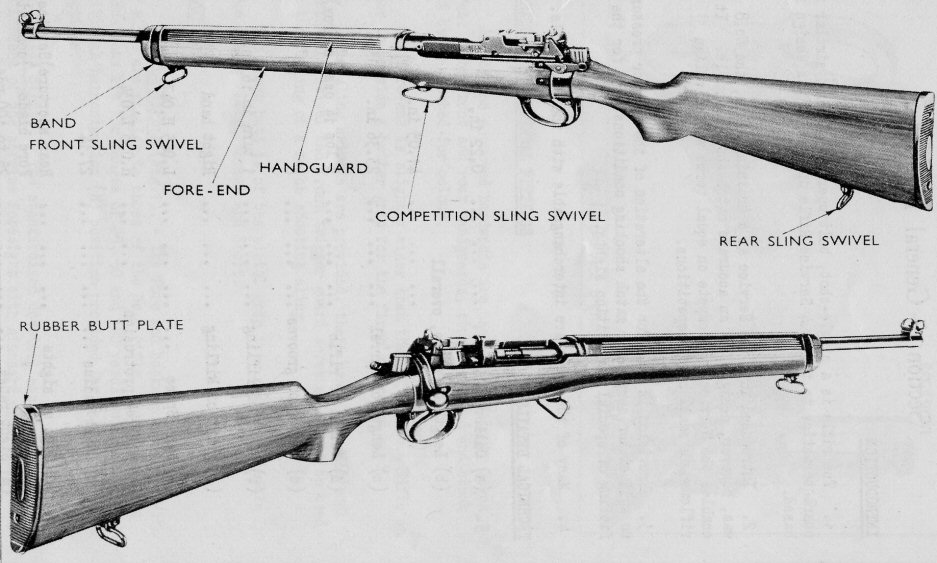

*****Frontispiece ... ... ... Rifle No.8

Mk.I

***Fig. 1 Service sights

2 Bolt

*******3 Safety devices

******************4

Cartridge platform and ejector

**********5 Trigger

mechanism

**************6 Double

action (service)

****************7 Single

action (competition)

******8 Sear release

************9 To remove

the bolt

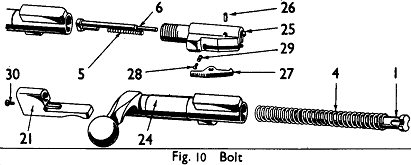

**10 Bolt

****************11 Fore-end and handguard

*******************12 Safety catch and looking

bolt

*******13 Trigger group

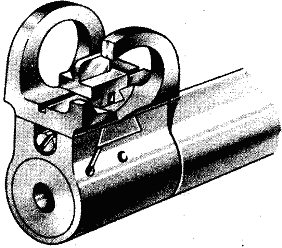

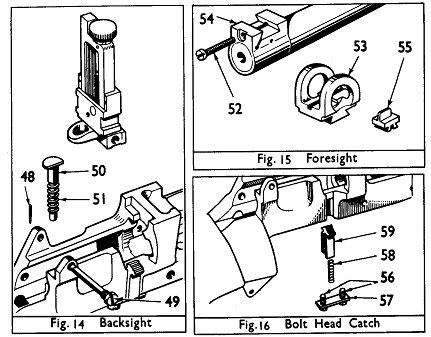

****14 Backsight

****15 Foresight

**********16 Bolt head catch

******17 Stock butt

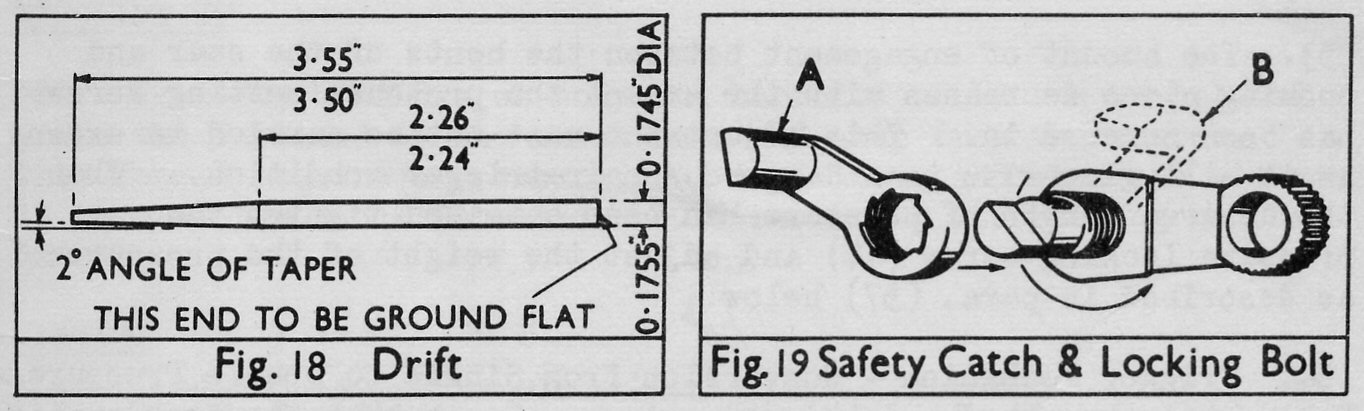

**18 Drift

********************19 Safety catch and locking

'bolt

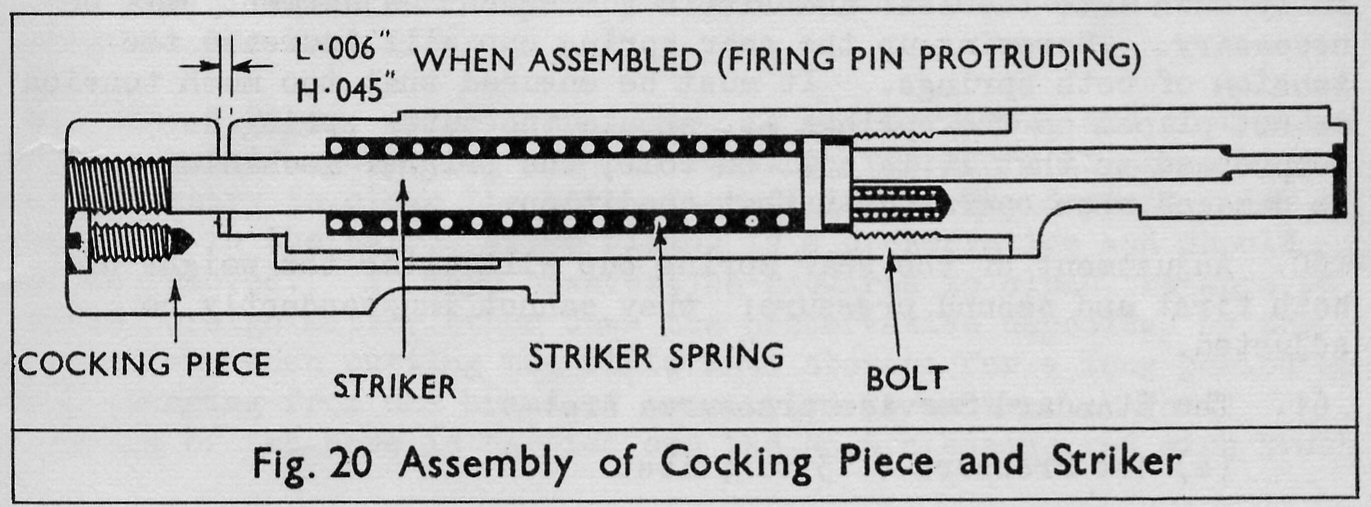

*****************20 Cocking piece and striker

**************************************************

Section 1 - General Description

INTRODUCTION

**1. The rifle is a single-shot,

bolt operated weapon, similar in

characteristics to the No .4 Service Rifle upon which its design is

based.

2. Introduced into the Service as a training rifle, the No.8

was, however, designed as an accurate match shooting rifle. It

enables the Services to compete on equal terms with civilian

riflemen in small bore competitions.

**3. Provision is made for the

alteration of the trigger pressures

to suit either service or match shooting conditions, and for the

fitting of special competition sights.

**4. Many of the parts are interchangeable

with the No .4 Rifle.

5. - TECHNICAL DETAILS

Calibre...........................0.22 in.

Length of rifle, overall......(normal butt) ........41.05 in.

Length of barrel .......23.36 in.

Weight of rifle .........8 Ibs 14 ozs. (approx.)

Number of grooves ....................6

Pitch of rifling .........1 turn in 16 in.

Twist of Rifling .........Right hand

Head Space ... .........L.045 H.047

Striker protrusion......H.038 L.O34

Sight radius ... .........27.14 in.

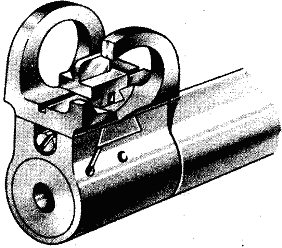

Type of sights .........Rear aperture )

*********************************Fore blade***)) in Service condition

Sight range ... .........25 to 100

FORESIGHT.............................................BACKSIGHT

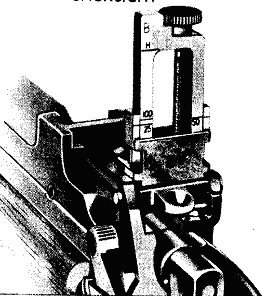

Fig. I Service Sights

FURNITURE AND EXTERNAL FITTINGS

6. Any of the approved hardwoods are used, i.e. Walnut, Beech, or Birch.

The front and rear handguards, stock fore-end and stock

butt being matched for colour.

7. The fore-end is slightly wider than that of the No .4 Rifle in

order to provide a better grip for the firer's forward hand.

8. Three sling swivels are provided, there being an additional

combination swivel and front trigger guard screw which can be used

for the fitting of a match shooting sling.

9. The stock butt is of the pistol grip type and is available in

three sizes; Long, Normal and Short.

SIGHTS

10. Service Sights (Fig.-l). - The fore and backsights issued with

the rifle are similar to those of the No .4 rifle, except that the

graduations are for ranges of 25, 50 and 100 yards, with an

additional harmonization (H) position provided for landscape target

practices.

11. Match Sights. - The standardized dovetail ensures quick

replacement of the service foresight with standard commercial

pattern match foresights.

Tapped holes in the body are provided, for the fitting of a trade

type match backsight.

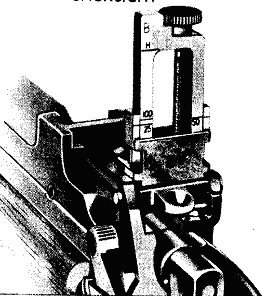

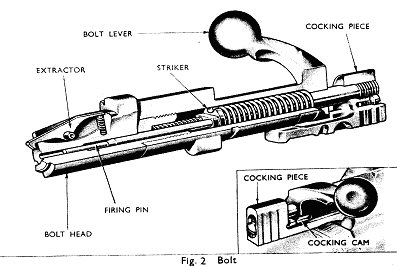

BOLT (Fig.2)

12. The No.8 differs from the No.4 in that cocking of

the action

is achieved by raising and lowering of the bolt lever only.

Although it is necessary to draw the bolt to the rear in order to

load, it is not necessary to do so merely to re-cock the rifle.

13. The rear end of the bolt houses a single cocking cam. When ,

in the withdrawn position the cooking piece is held to the rear

against the rear end of the bolt.

14. The striker is shorter than that of the No.4 rifle and is

designed to drive forward an independent firing pin which is housed

in the bolt-head and is off-set radially in order to strike the rim

of, and fire, the 0.22 in. cartridge.

BODY

15. The body is either a modified. No.4 rifle bolt body, or is a newly

manufactured body, similar to that of the No .4 rifle, with certain

internal machining operations eliminated.. The main differences

are:-

(a) The boltway is bored larger at the front end. to permit

entry of the rear end of the No.8 rifle barrel.

****(b) The lower part of the body is widened,

to accommodate the

cartridge platform.

(c) The rib on the No.4 rifle body, which retains the No.4

rifle bolt-head is machined off.

16. Tapped holes on the left side of the body are provided to

take a special match backsight.

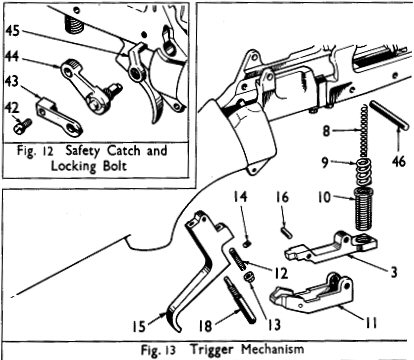

TRIGGER MECHANISM

17. The trigger of the No.8 rifle can be adjusted to give either

the service double pressure, or a single match pressure. The

weight and length of the pressure can be adjusted in both cases.

**18. During release of the sear,

the cocking piece is supported by

the sear cradle. This eliminates drag between the sear and

cocking piece bents and ensures a clean and crisp let-off.

BARREL

**19. The barrel is shorter

and heavier than that of the No.4 rifle.

Its extra weight reduces to a minimum the vibrations set up in

firing and ensures a high degree of accuracy.

20. It has a plain bearing in rear of the breeching up thread;

this brings the chamber further to the rear and permits quick

loading in the lying position.

***21. The rifling is tapered,

being deepest at the breech end and

running out to almost bore diameter at the muzzle. The tapering

of the rifling gives an improved gas seal and also removes the

initial engraving from the bullet by the time it leaves the muzzle.

The purpose of this is to improve the standard of accuracy with

varying brands of ammunition.

*****22. The chamber has a plain taper

and the breech face is counter-

*******bored to take the rim of the cartridge;

it is further counterbored

to accommodate the rim of the bolt-head.

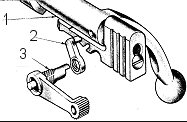

Fig.3 Safety Devices: (1) Bolt body; (2) Locking bolt;

(3) Safety catch

23. The applied, and. mechanical safety devices are similar

to those

of the No .4. rifle except for the following differences:-

(a) The safety catch engages in a hole in the bolt, instead

of in a cam slot.

(b) The rear safety recess on the cocking piece of the No.8

rifle is semi-circular and, unlike the No.4 rifle, does

not cause the cocking piece to be withdrawn when the

safety catch is applied, with the cocking piece in the

forward, position.

STOCKING

24. The bearings are the body seating, the reinforce, the middl

of the barrel and. the muzzle.

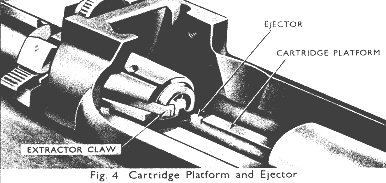

CARTRIDGE PLATFORM AMD EJECTOR (Fig.4)

25. There is no magazine. A cartridge platfonn is situated just

in rear of the chamber. The ejector is integral with the

cartridge platform.

CONVERSION TO L2A1

26. Some rifles will be converted, for use with R.A.C. miniature

range training by the removal of the foresight and. backsight and.

hand.guard.8 and. stocks. Such rifles will be known as "Rifle,

aiming, 0.22 in. L2A1".

Section 2 - Operation

LOADING:

27. As there is no magazine, the rifle must be loaded by hand for

each shot, as follows:-

(a) Push safety catch fully forward.

**************(b) Raise the bolt lever and

draw bolt fully to the rear.

******************(c) Place a cartridge in

the groove of the cartridge platform

then press the round forward with the thumb or finger

until the bullet has entered the chamber and resistance is felt.

*************(d) Grasp the knob of the lever,

thrust the bolt sharply

forward as far as it will go, then rotate the bolt lever

downwards, ensuring that it is fully down.

*****************(e) Repeat operation (b) to

(d) for each successive round.

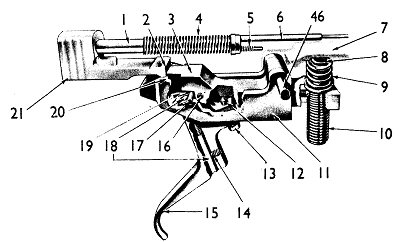

Fig. 5 Trigger mechanism

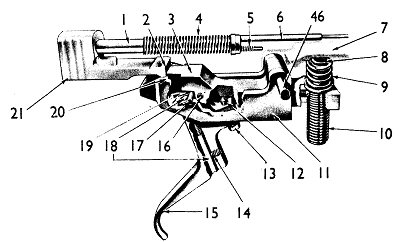

TRIGGER MECHANISM (Figs. 5, 6 and. 7)

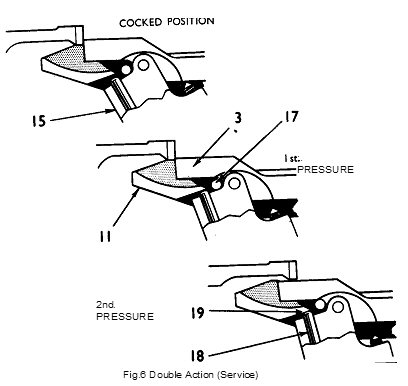

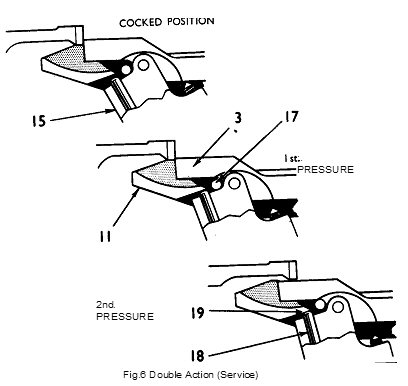

28. Double Pressure - Service Condition (Figs. 5 and6) - When,

with the weapon cocked, the trigger (15) is pressed, the trigger

rotates initially about the cradle pin (17) as a fulcrum, levering

down the sear (3) in it's cradle (11), and rotating it about its

axis pin (46). This compresses the inner and outer sear springs

(8) and (9) and produces the first pressure. Continued pressure on

the trigger causes the protruding end of the pressure setting screw

(18) to contact the flat on the underside of the sear cradle (19),

to which the fulcrum point is then transferred and the leverage

altered. This produces the second pressure.

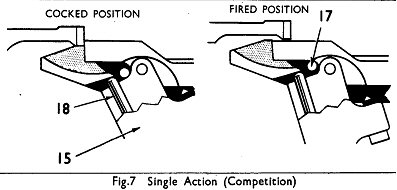

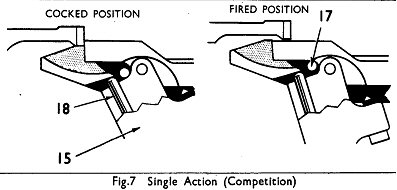

29. Single Pressure - Match Condition Figs. 6 and. 7).

- When it

is required, to adjust the trigger mechanism to a single pressure

for match conditions, the outer sear spring (9) is removed.. This

considerably reduces the trigger pressure. The pressure setting

screw (18) is then screwed in sufficiently for the trigger (15) to

rotate solely about the end of the screw and to avoid all initial

contact with the cradle pin (17).

30. Weight of Trigger Pressures. - The weights of both single and

double action pressures can be adjusted to fine limits by adjusting

the compression of the inner sear spring (8). This is

accomplished by screwing the sear spring cup (10) in or out.

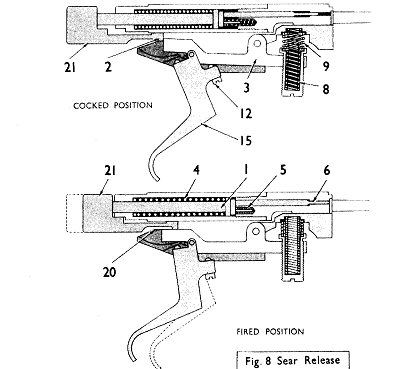

SEAR

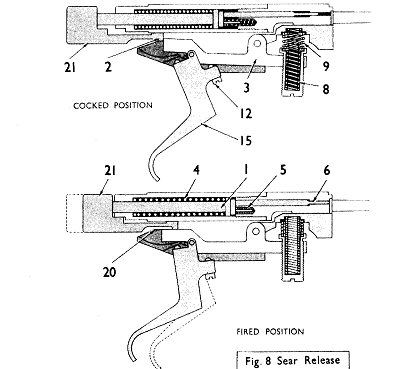

31. Sear Engagement (Fig.8). - The engagement of the sear (3) and

the bent of the cocking piece (2) is adjusted, before the weapon

leaves the factory, to a height of 0.03 in. by means of the trigger

setting screw (12). This setting normally should not require

adjustment.

32. Sear Release (Fig.8). - The pressure exerted by the compressed

sear springs (8 and. 9), transferred via the sear (3) and trigger

(15), combined with the direct pressure on the trigger, produces an

upwards thrust through the sear cradle pads (20) on to the base of

the cocking piece (21). This upwards thrust counterbalances the

downward drag of the bent of the sear on the bent of the cocking

piece (2) and prevents any axial movement of the bolt. When the

sear is released, the striker spring (4) carries forward the cocking

piece and striker (21 and 1) to drive the firing pin (6) forward on

to the rim of the cartridge, compressing the firing pin spring (5)

in so doing.

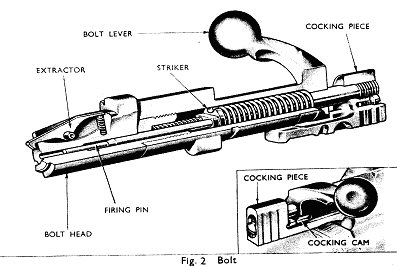

WITHDRAWAL OF THE FIRING PIN

35. When, after firing, the bolt lever is raised., the striker (1)

and. cocking piece (21) are withdrawn by the action of the stud on

the cocking piece in the cam slot of the bolt - similar to the

action of the No .4 rifle. The withdrawal of the striker allows

the firing pin spring (5) to re-assert itself and withdraw the

firing pin.

EXTRACTION AND EJECTION

54. When the bolt lever is raised, and the bolt withdrawn, the

empty case is removed from the chamber by the claw of the extractor

(Fig.4) pulling on the rim of the case. The empty case is held

between the claw of the extractor and the face of the bolt during

withdrawal of the bolt until the ejector (Fig.4) strikes the rim of

the case and ejects it from the rifle.

Section 3 - Servicing

STRIPPING

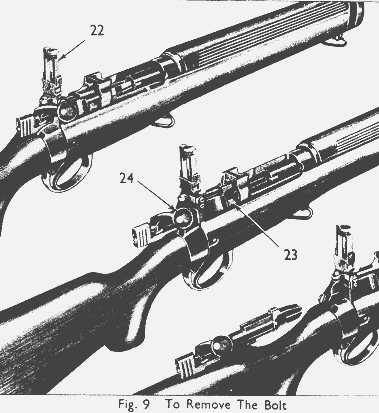

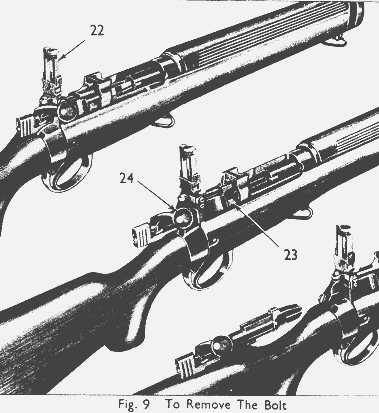

35. To Remove Bolt From Rifle (Fig.9). - Raise the backsight (22);

press down the bolt head catch (23); lift bolt lever (24) and pull

bolt back to its full extent. Release bolt head catch; raise

bolt head, and withdraw bolt from rifle.

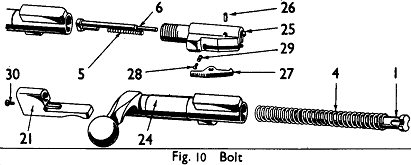

36. To Strip Bolt (Fig.lO). - Unscrew the bolt head (25), and.

pull out the firing pin (6) and firing pin spring (5)- With a

suitable punch, drive out the extractor pin (26); remove extractor

(27), extractor plunger (28), and extractor spring (29). Remove

the striker screw (50) from the cooking piece (2l), and unscrew the

striker (1) with the "Tools Striker No.2" as used. with the No.4

rifle. Remove striker and striker spring (4) from the bolt (24).

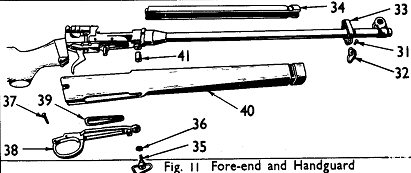

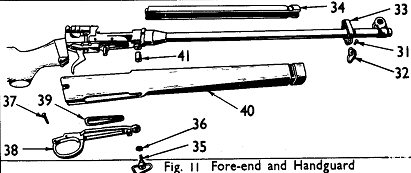

57. Fore-End and Handguard (Fig.n). - Remove the front swivel

screw (51) and remove the swivel (52) and band (55). Iiift off the

handguard (54), remove the front trigger guard screw (55), and

remove the spring washer (56). Remove rear trigger guard screw

(57); remove trigger guard (58) and trigger guard filler (59).

Remove the fore-end (40), and collar (41)o

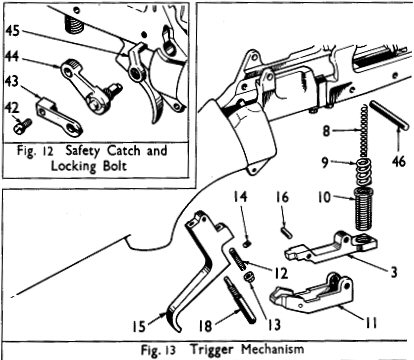

38. Safety Catch and Locking Bolt (Fig.12). - Remove the locking

bolt screw (42); looking bolt spring (43) and. remove the locking

bolt (44) and safety catch (45) from their housing. Unscrew safety

catch from locking bolt.

39. Trigger Mechanism (Fig. 13). - Drive out the rear cartridge

platform pin (46) and. pull trigger assembly downward out of the body.

Remove the inner and outer sear springs (8 and 9) and slide the sear

cradle (11) down over the trigger (15). Take out the trigger pin

(16) and separate the trigger from the sear (3). Unscrew the sear

spring cup (10) from the sear.

40. The sear bolt and. its spring, which are housed in the sear to

check rotation of the sear spring cup, are burred in and cannot be

removed. To strip the trigger, remove the pull-off locking screw

(14) and pull-off setting screw (18); remove the trigger setting

screw nut (13) and trigger setting screw (12).

41. Cartridge Platform. - The cartridge platform should not be

removed., since the hole for the front pin is drilled on assembly,

making the platform a special fit to the body. If through wear or

breakage it is required to replace the ejector this will be done as

a factory repair.

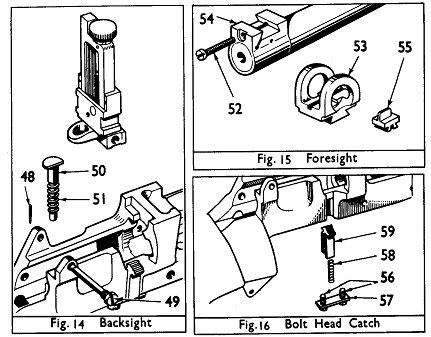

42. Backsight (Fig.14). - Tap out the backsight axis pin

retaining pin (48) and drive out the backsight axis pin (49).

This releases the backsight assembly. Lift the backsight plunger

(50) and its spring (51) from their housing.

43. Foresight (Fig.15). - Unscrew the clamping screw (52) and

slide the foresight protector (53) out of its dovetail in the

barrel band (54). Tap the foresight (55) out of the dovetail in

the foresight protector.

44. The barrel band is pinned and sweated on to a reduced

diameter at the end of the barrel and must not be removed.

45. Bolt Head Catch (Fig.16). - Undo the two screws (56)

holding

the breech bolt head catch retaining plate (57); lift the spring

(58) and breech bolt head catch (59) from their seating.

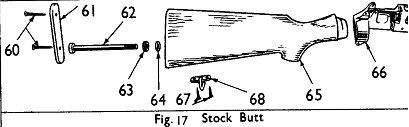

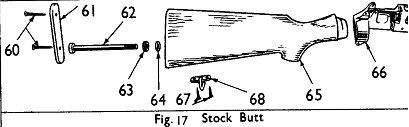

46. Stock Butt (Fig.17). - Remove the two stock butt plate screws

(60) and lift off the butt plate (61). Remove the stock bolt (62)

and take the stock bolt spring washer (63) and washer (64) out of

the stock butt (65). Pull the stock butt from the body socket (66).

Remove rear swivel screws (67) and rear swivel (68).

47. The rifle should be assembled in the reverse sequence of the

order of stripping. The only difficulties likely to be experienced

are in the securing of the trigger group to the body; screwing the

cocking piece onto the striker, and in assembling the safety catch

and locking bolt. Instructions on these points are given below.

ASSEMBLING

48. Trigger Group. - To enable the rear cartridge platform pin to

be driven in to secure the trigger group, the holes in the rifle

body, cartridge platform, sear cradle, and sear must all be exactly

aligned at one and the same time. This is extremely difficult

without the aid of a guide drift, and damage to components will

result if any attempt is made to drive the pin through the holes

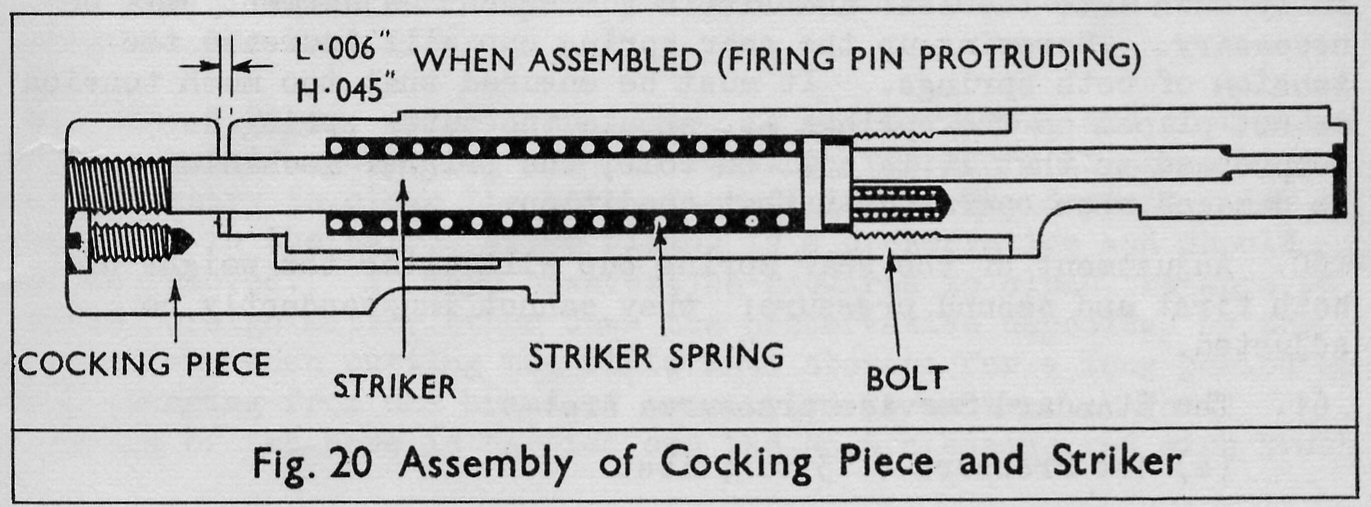

when they are aligned by any less precise method.

49. The drift used should be in accordance with the dimensions

shown in Fig.18. The holes in the trigger group should be aligned

as nearly as possible by eye and the tapered end of the guide drift

passed through them; the guide drift should be pushed or gently

tapped through until the ground end is flush with the body of the

rifle. The end of the rear cartridge platform pin should then be

placed on the end of the guide drift, and the guide drift driven

through the rifle body by the pin. The ends of the pin and the

guide drift should be kept in close contact with each other during

the time the pin is being driven through.

50. Safety Catch and Locking Bolt (Fig.19). - It is important

that the threads should be picked up correctly when the locking

bolt is screwed on to the safety catch. To assist in correct

assembly, fig.19 shows them (A) positioned as they should be before

engagement of thread, and (B) when screwed fully home.

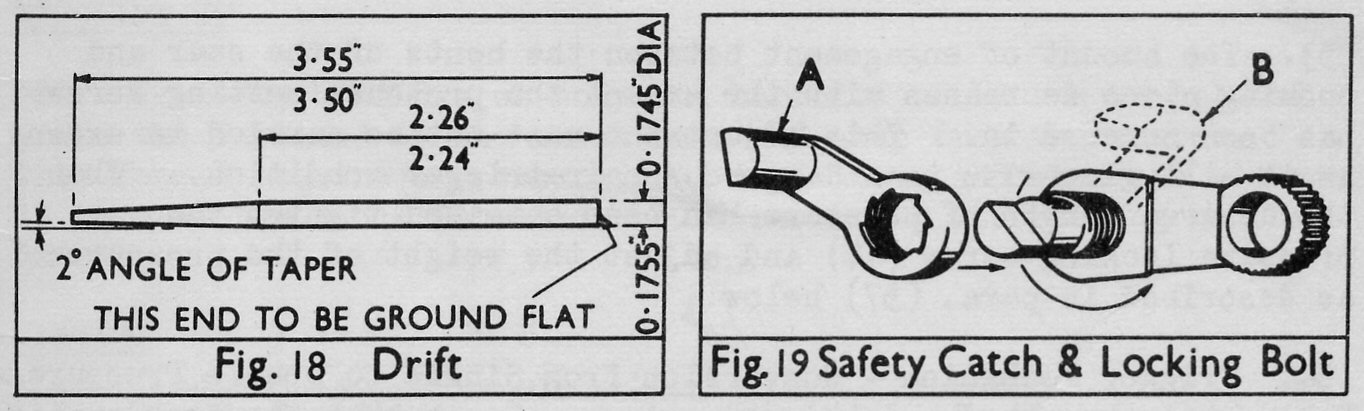

51. Cocking Piece (Fig.20). - To ensure correct functioning it is

essential that the cocking piece should correctly be assembled to

the striker. The two components should be assembled as shown in

the illustration.

ADJUSTMENTS

52. Trigger Mechanism - Conversion from Double to Single Pressure.

Remove the trigger guard and trigger group. Remove the outer seal

spring (9) and re-assemble with the inner spring only (8). Loosen

the pressure locking screw (14). Screw in the pressure setting

screw (18) a half-turn at a time until a single pressure is

obtained. When the weapon is cocked the pressure setting screw

should now bear on the underside of the sear cradle web, not on the

sear cradle pin which is not used as a fulcrum in single pressure

match condition.

53. The amount of engagement between the bents of the

sear and.

cocking piece decreases with the amount the pressure setting screw

has been screwed in. This adjustment must not be carried to excess

as it will give rise to a dangerous hair-trigger condition. When

the desired length of pressure has been obtained, tighten the

pressure locking screw (14) and adjust the weight of the pressure

as described in para. (57) below.

54. Trigger Mechanism - Conversion from Single to Double Pressure.

Remove trigger guard and trigger group. Screw home the sear spring

cup, replace the outer sear spring (9), and re-assemble the trigger

mechanism. Loosen the pressure looking screw (14), and screw out

the pressure setting screw (18) a half-turn at a time until a

double pressure is obtained.

55. When the weapon is cocked the flat on the top of the trigger

should now bear against the cradle pin (17). The length of the

pressures can be adjusted by screwing the setting screw in or out.

56. Tighten the pressure locking screw and adjust the weight as

described in para. 57 below.

57. Weight of Trigger Pressure. - For single pressure action,

with the inner sear spring only in position, the trigger pressure

weight can be adjusted by screwing the sear spring cup (10) in or

out. This alters the tension of the sear spring. One quarter

turn (one click) of the sear spring cup makes a difference of 2.5

ounces to the pressure weight.

58. The minimum match condition weight of 3 lbs. can be adjusted

within close limits.

59. For double pressure trigger action, both sear springs must be

in position. The sear spring cup initially should be screwed

fully down into the sear and little subsequent adjustment will be

necessary. Screwing up the sear spring cup will increase the

tension of both springs. It must be ensured that too much tension

is not placed on the springs as, should the outer spring be

compressed so that it is coil on coil, the trigger mechanism will

be damaged when operated in that condition.

60. Adjustment of the sear spring cup will alter the weight of

both first and second pressure; they cannot independently be

adjusted.

61. The Standard Service pressures are:-

(a) 1st Pressure 3 to 4 lbs.

(b) 2nd Pressure 5 to 6.5 lbs.

STOCKING-UP

62. Test for bearings on body and barrel. Hold the barrel and

press the fore-end of the stock fore-end away from the barrel.

This should require a pressure of 3 to 5 Ibs., and when the pressure

is removed the stock fore-end should return to its seating on the barrel.

ZEROING

63. The No.8 rifle is zeroed, by alterations to the size and

position of the foresight, in a manner similar to that used with the

No.4 rifle. The foresights used are the same as those issued for

the No.4 rifle. They are 8 in number ranging from -0.03 in. to

+0.075 in. in steps of 0.015 in. One change of foresight (of

0.015 in.) will make a vertical alteration of MPI of approximately

1/2 in. at 25 yards.

64. The rifle should be zeroed so that the MPI is at the point of

aim with the backsight set for the range used.

65. The foresight should be set laterally with the Tool, Foresight

cramps No.3.

ALTERING LENGTH OF BUTT

66. Three different lengths of butt, long, medium and short are

provided. The variation is the same as for the No.4 rifle - 1/2

inch each side of a medium length of approximately 13 inches.

67. The method of stripping the butt for exchange of size is

shown in Section 1, para.46.

CARE AND CLEANING

68. The exterior and working parts should be cleaned in the same

manner as the No.4 rifle.

69. The 0.22 in. ammunition issued to the Services, and most makes

of commercial ammunition, are non-rusting, therefore it normally is

not necessary to clean the bore after firing. The deposit

remaining in the barrel after firing is a preservative and should

not be removed. It may, however, be required to clean the bore to

remove foreign matter other than the preservative deposited by the

ammunition, when putting the rifle into storage for a long period or

when changing from one brand of ammunition to another. When

cleaning of the bore is carried out the No.6 cleaning rod with Brush

and Cleaner should be used. Regulation flannelette, size 2

x

1 .1/8 in., and oil should be used. It is not necessary to use

boiling water.

ADDITIONAL TECHNICAL POINTS

70. Mainspring. - The bolt should be removed from the rifle in

order to check the tension of the mainspring. The tension of of

the spring is ascertained by weighing the effort required to move

the

cocking piece in both the fired and cocked positions.

Mean weight in fired position = 13 lbs.

Mean weight in cocked position = 15.25 lbs.

If in the fired position the weight falls below 12 lbs. the

mainspring should be replaced.

71. Extractor. - The approximate mean weight exerted by the

extractor spring is 3 lbs. This should be tested by exerting

pressure on the tail of the extractor, as it is difficult to weigh

by lifting the claw and may cause damage to the extractor.

72. Sear and sear cradle. - The setting of sear and

sear cradle

should be checked from the boltway, on the assembled rifle, to

have a clearance of 0.03 in.

73. Barrel. - Gauge bore with cylindrical acceptance plugs

L.0.216 inch must run. The barrel should be free of any lateral

influence by the fore-end.

Section 4 - Examination

BOLT

74. Examine for wear, corrosion, and burrs. Remove all burrs by

stoning, taking care to avoid removing any metal (other than the

burr) from the rear faces of the locking lugs and the cartridge face.

75. Examine the bolt head for corrosion, wear, and burrs.

Remove any burrs by stoning. Ensure that the extractor, extractor

plunger, and extractor spring work freely in their recesses.

76. Examine the extractor and firing pin for wear, damage,

corrosion and distortion. Examine the extractor spring, firing pin

spring, and striker spring for corrosion, fractures and collapsed coils.

77. Examine the cocking piece and striker for burrs, distortion

and damaged threads.

BODY

78. Examine for corrosion, burrs, distortion and fractures.

Ascertain that the cartridge platform pins are a tight fit.

TRIGGER GROUP

79. Examine the components for burrs, corrosion, distortion and

damaged threads.

80. If the top corner of the sear bent is rounded, a little metal

may be stoned from the upper surface to correct it. Care must be

taken to avoid altering the angle between the top and rear faces of

the sear, and stoning must not be resorted to unless it is

considered that the fault has developed to an extent which will

cause a "woolly" release of the cocking piece.

FURNITURE

81. Examine the furniture for cracks or other damage and ensure

that the stock butt is a firm fit in the butt socket. Examine the

stock fore-end and handguard for warping.

Section 5 -Competition Shooting

82. The sights issued with the No.8 rifle are replicas of those

on the full-bore service rifle and are designed primarily for use

under service firing conditions. For competition shooting under

Match conditions, more accurate sights, capable of fine adjustment

will be required. These match sights will not be issued, but will

be provided, if required, by individuals, or rifle clubs in the same

way as special sights are used for S.R.b shooting at Bisley and elsewhere.

83. To assist in the fitting of Match backsights to the No.8 rifle,

three holes have been provided on the left side of the body. The

three holes are tapped for 4 B.A. and 3 B.A. threads and are

normally closed with a cheese-headed screw to prevent the ingress

of dirt. The screws are removed before fitting a Match backsight.

84. It may be necessary to remove the Service backsight before

certain types of Match sights can be fitted to the rifle.

85. The Service foresight is designed for easy removal when

it

required to fit a Match foresight of the tunnel variety. The

dovetail on the block is of standard size and will take the normal

commercial pattern of foresights. When fitting certain types of

commercial foresights it may be necessary to make a small groove

in the underside of the sight in order to accommodate the clamping

screw. It is emphasized that if any modification is necessary it

must be made to the purchased sight - not to the foresight block

of the rifle.

86. Details of the various trade pattern match sights suitable

for fitting to the No.8 rifle, together with advice and information

on small bore matters generally, may be obtained from the Army Rifle

Association, or from the National Small Bore Rifle Association.

Back to: Rifle No.8 page

Return to: TOP of PAGE

See this website's Raison d'être